BIOWORKS® construction design

The special basin design: safe, durable and cost effective

Concrete is not always the best building material: BIOWORKS® is increasingly counting on earthen basin type and compact module construction.

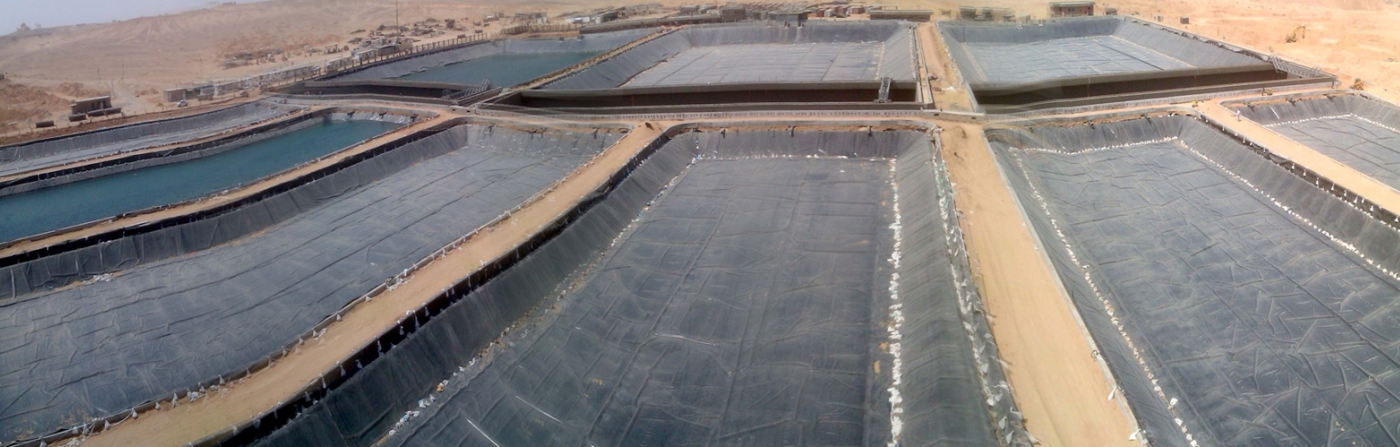

Conventional waste water treatment plants are usually made from concrete. However concrete is not cost effective, the construction is time-consuming and expensive. BIOWORKS® offers our clients the chance to use the fundamentally less costly earthen basin construction with HDPE-lining. Here the basin is excavated from the ground and the dug out soil-material is used to build the surrounding dams. The HDPE lining is rolled onto the basin and the seams are welded tight. This type of basin sealing is robust, durable and has been approved now for many decades. It is also providing the client with the safety of latest European quality and security standards and regulations.

The advantages:

-

Longer lifetime than concrete: Concrete basins, especially if they are exposed to corrosive ground water or critical sewage, can be damaged seriously after just a few years. HDPE linings have been proven to be extremely durable and have sustained tightness for more than 30 years (for example in garbage landfills)

-

Significantly lower investment costs

-

more security because - contrary to concrete- the flexible earth basin construction with HDPE lining is not vulnerable to settlings of the underground soil or earthquakes.

-

drastically reduced construction time (only a third of concrete basins)

-

superior structural characteristics than large concrete basins - process volume can be enlarged, this directly benefits the process.

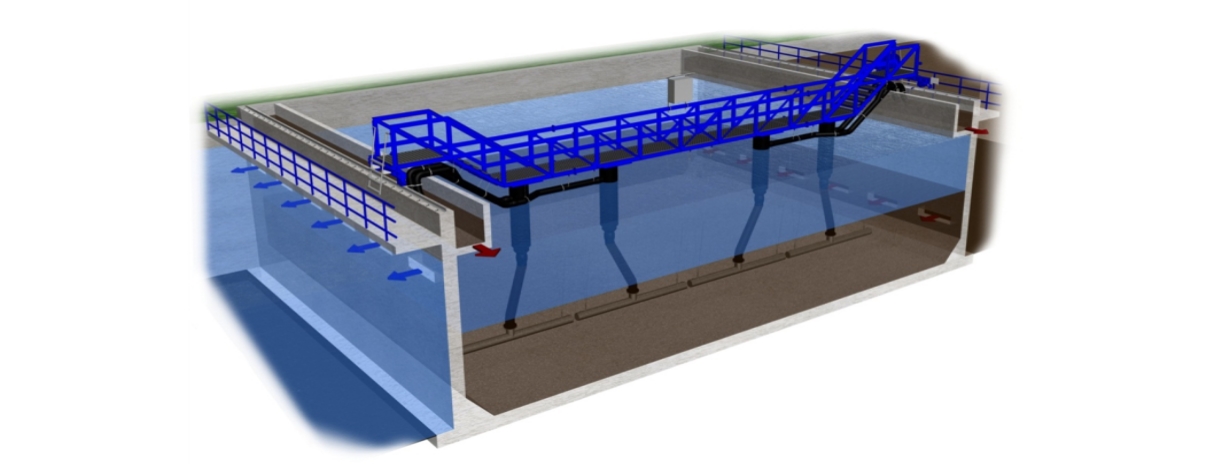

One basin module fits several treatment steps

Traditional waste water treatment plants commonly are composed from several single concrete basins, which are linked by interconnecting pipework and sometimes even need a pumping stations. The BIOWORKS®-process requires only one basin module which is separated in several single treatment steps. Consequently the clarifier is embedded as well into this module. The main advantages of this embedded design:

-

reduced footprint because of compact construction.

-

waste water is flowing by gravity through the single process steps. There is no need for interconnecting pipework.

Typical earth basin construction with HDPE-lining and embedded clarifier wall

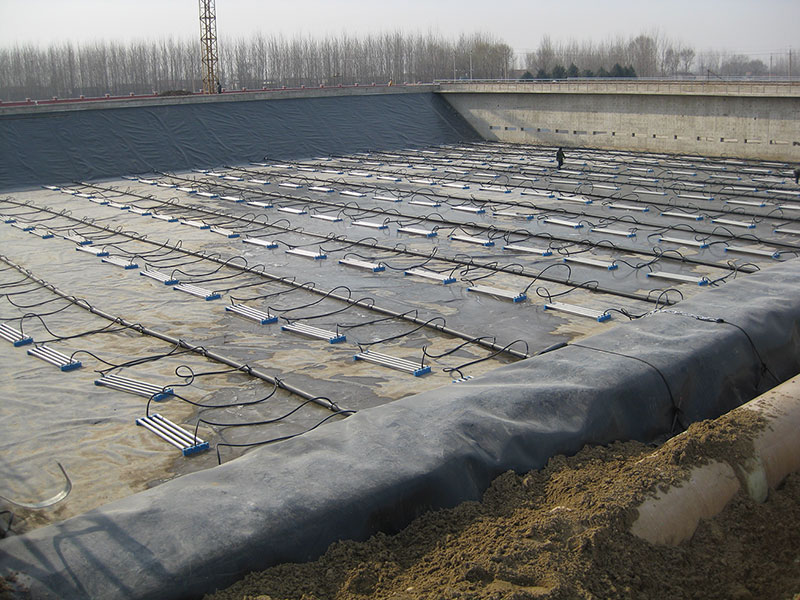

Finished earth basin with HDPE lining and pre-assembled diffuser elements

A clarifier must not necessarily be circular – the geometry

The traditional clarifier has a circular shape. Especially under high hydraulic load, turbulence in the inlet structure of the clarifier can occur because of high inlet velocities and settling sludge can be stirred up. Sometimes this entrance structure has to be modified with additional baffle plates to calm down these turbulences.

The BIOWORKS®-process is utilizing a rectangular basin form, which optimizes the settling characteristics of the inflowing water. The advantages of this favourable geometry are significant:

-

Because of direct wall connection to activated sludge basin generally more inflow area.

-

Low inflow and effluent velocities

-

Undisturbed settling conditions for the mixed liquor

Rectangular Basin Clarifier