Custom skid mounted complete Ozone Generator System with feed pump, distribution pump, contact tank, oxigen generator, PLC, and residual ozone monitor.

WE BUILD OUR OWN OZONE GENERATORS

RUGGED - ROBUST - RELIABLE

The UET WATER (UET-OzoStar) equivalent series of ozone generating systems are designed and sized to cover a wide range of commercial applications using standard designs to provide reliability, cost effectiveness, high efficiency and service accessibility.

The ozone units are cabinet mounted and designed for capacities up to 168 g/hr in oxygen. The units are shipped complete with a separate oxygen generator, and all optional controls and accessories to meet the project requirements such as contacting vessels, ozone injectors, pumps and ozone destructors.

Typical Applications:

-

Bottled Water & Washers

-

Beverage Applications

-

Laboratory Pilot Testing

-

Cooling Tower Recirculating

-

Water Treatment

-

Food Processing

-

Clean-In-Place

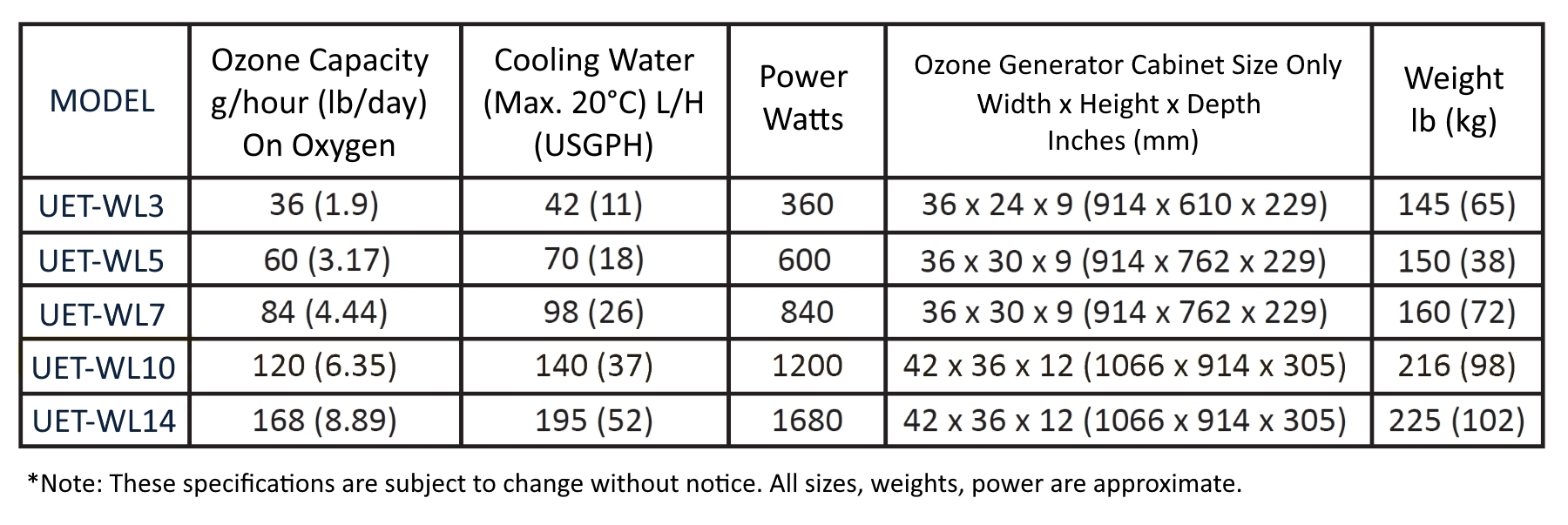

SPECIFICATIONS:

STANDARD FEATURES:

- Water cooled for maximum performance

- Continuously variable production control

- 304 Stainless Steel cabinet

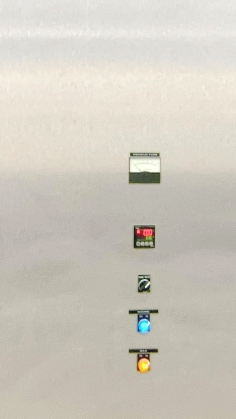

- Panel mounted instruments & controls:

- Gas Flow Rota-meter

- Power Meter

- Power Regulator

OPTIONAL FEATURES:

- Water flow solenoid

- ORP feedback Control (4-20mA)

- Feed & Delivery Pumps

- Turnkey solution skid mounting

- Ozone Residual Analyzer

- Ozone contact tank

- Stainless steel frame mounted

- PLC Control & PLC HMI Screen

Optional Sanitary Feed & Delivery Pumps Shown

All ratings are based on ozone concentrations of 6% wt in Oxygen at 20c cooling water temperature and 9 psig application pressure. Ratings at other conditions available.

Sample Oxygen Concentrator Unit

Sample Interior of Ozone System Cabinet

Sample Skid Mounted Option

Type WL7 Model With Stainless Steel Cabinet

HOW OZONE TREATMENT FUNCTIONS:

Ozone is basically an unstable form of pure oxygen. Ozone is a strong oxidizing agent similar to chlorine, and is used just about the same way. It is used to kill bacteria and viruses that cause disease. There is research that has shown that ozone is more effective than ultra-violet or chlorine disinfection for treating Cryptosporidium parvum or Giardia lamblia. Ozone can be used also as a pretreatment method before the reverse osmosis system or an ion exchange resin system to control biofouling, as some membranes and resins can deteriorate and get damaged by chlorine.

Ozone is produced when oxygen molecules (O2) are split and recombined into ozone (O3). The reaction from (molecular) oxygen to ozone requires energy. In most commercial applications, ozone is produced when a gas containing oxygen is passed through an electrical field separated by two electrodes. When oxygen molecules in the gas interact with the electrical field, they split and recombine, forming ozone. This is the Corona Discharge ozone generation process. Ozone’s unique oxidation process creates advantages for water treatment systems. Ozone is also a flexible and versatile tool to improve performance in water treatment processes. Ozone has many beneficial properties that can optimize water systems and allow you to meet your goals more easily and at lower cost.

Oxygen Generator & Contact Tank Shown

Ozone may not kill large organisms or remove inorganic chemicals, or heavy metals or large cysts, so these other items should be treated by filtration or other treatment prior to ozone treatment. Ozone is also effective in controlling color, taste, and odor problems. Ozone oxidizes manganese and iron into solid particles that can be filtered and eliminated.

Ozone treatment systems are usually installed as a primary point-of-entry sterilization system. Ozone will mix with the water, bubbles are created to ensure that the ozone is in contact with the untreated water. To have the most effective treatment, its best to have good turbulence and differential pressure. The water flow rate is important to size an ozone system.

Once the water flow rate is determined, then we determine the ozone contact time within the water to determine the most efficient effectiveness of ozonation. Ozone requires a shorter contact time than chlorine in most cases. Also in most cases, the lower the water temperature, the more ozone is dissolved in the water. Ozone is effective over a wide range of pH, but a pH above 7 increases the treatment efficiency. The amount of ozone required depends on the level of contamination in the water that needs to be treated. If substances in the water to be treated react with ozone, part of the ozone produced and injected in the water is used up, which will leave less ozone available to treat the targeted contaminants.

Oxygen Generator Accumulation Tank

Ozone system capacities: The ozone dosage needed for a project will depend on the raw water quality. Typical ozone dose is 1.0 to 2.0 milligrams per liter. This is sufficient to kill most bacteria and control tastes and odors. The storage tank capacity determines how much water is available for use.

Service of ozone systems: Ozone systems do not require extensive service.

The disinfection process does not occur beyond the treatment unit. Ozone has an active residual time measured in minutes.

Ozone is an environmentally friendly technology that does not create any chlorinated disinfection byproducts. Ozone decays naturally within minutes into oxygen and increases dissolved oxygen levels.

Ozone also improves the performance of other processes in a water treatment process. The benefits to other processes include reduced costs and increased lifespans.

Most people can smell ozone at a concentration of 0.01 milligrams per liter (well below the level for general comfort) and breathing traces of ozone for a few minutes is of little health concern. For safety, any residual ozone in the vent gas should be vented to the outside of the building.

Optional Residual Ozone Monitor Analyzer

Contact us today to size the right ozone system with the appropriate options for your custom application.