Efficient and economic waste water treatment:

With worldwide rising awareness for the protection of our environment, requirements for waste water treatment are increasing, carbon-nitrogen, and phosphorous compounds have to be eliminated to the greatest possible degree. The BIOWORKS® process not only guarantees our client that this target is achieved, it furthermore enables him to do so under low investment and O&M costs. Because we have the lead on the full design of the entire process solution, we can guarantee that effluent values are fully complying with any legal requirements our clients benefit from this high level of security. Efficiency is achieved by innovative solutions in every single step of the process.

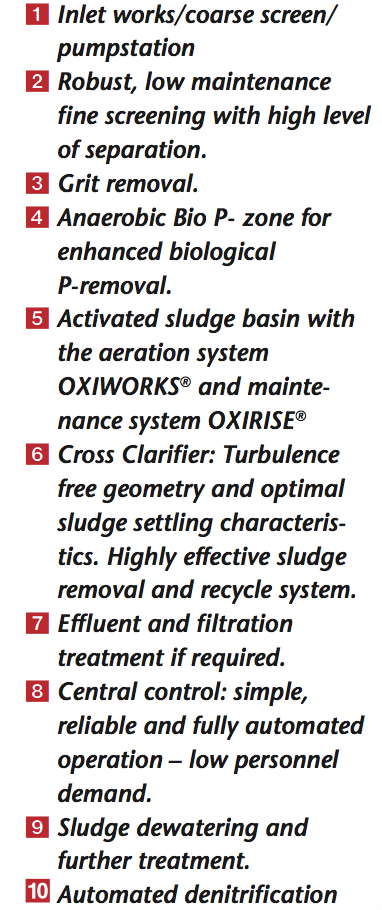

Typical single process steps of a BIOWORKS®-treatment plant:

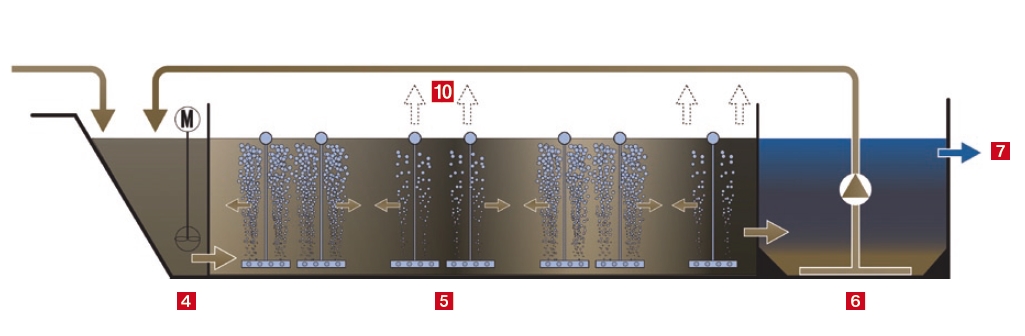

The biological stage within the Bioworks®-process

Waste water contains many nutrients in the form of carbon and nitrogen compounds, phosphates, proteins and other components. After mechanical-pre treatment 2 + 3 the biological process starts with the Bio-P zone 4. Robust and maintenance low submerged stirrers are mixing the inlet with return sludge. In this selector basin organic acids are created under an anaerobic ambient, this enables the bacteria in a later aerobic stage to absorb more phosphates than usually. Effluent values of total P < 1 mg/l without chemical dosage are possible under the condition of favorable nutrient composition. The water-sludge mixture flow through the separation wall into the aerobic reactor.

The most important process step is conducted in the activated sludge basin 5. Carbon and nitrogen compounds in the waste water are aerobically digested by the various kinds of bacteria living in this basin. The aeration system OXIWORKS® enables the bacteria to work as efficient as possible, while the whole basin is mixed properly and efficiently by the fine bubbling

suspended aeration system.

Within the so called denitrifi cation phase lays another important task for the biomass in the activated sludge basin. Smart control of the air flow 10 allows to create anoxic zones within the activated sludge basin. Oxygen which is bound to nitrate is split off and utilized by certain specialized bacteria in order to oxidize carbon compounds, the nitrogen is released to the atmosphere. In the clarifi resection the biomass ist separated from the clear water by settling. The valuable biomass is withdrawn from the basin bottom of the clarifier and is recycled to the inlet of the basin.

Clear product water is streaming from the effluent of the settling zone 7. In cases of strict requirements for effluent quality a tertiary filter stage can follow (optional).